Maintaining plant viability, maximising yields, and preserving cannabinoid and terpene profiles depend on grow room temperatures and establishing a favourable and effective temperature control in grow rooms in tropical settings. Stress is significant for cannabis plants, particularly in warm temperature areas, as it can limit growth and reduce the quality of the final crop. Growers suffer heat stress, less photosynthesis, and early flowering if they don’t keep appropriate temperature control. For cannabis growers in these harsh circumstances, this article is full of advice on how to control the grow room temp too high, and establish a favourable habitat for their plants.

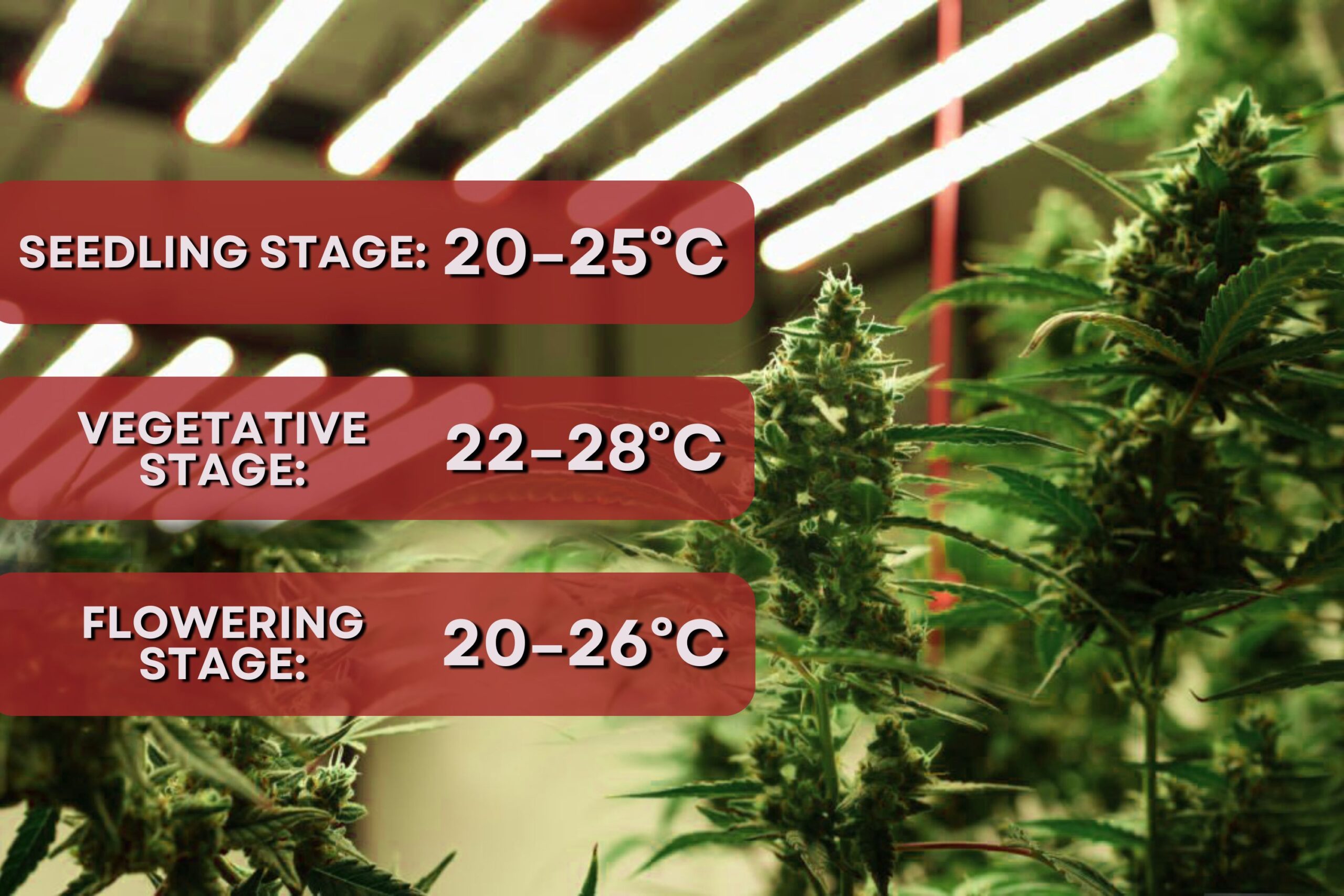

The Ideal Temperature Range for Cannabis Growth

Compared to its growing stage, cannabis thrives best within certain temperature ranges:

1. Seedling/Clone Stage: 20–25°C (68–77°F)

2. Vegetative Phase: 22–28°C (72–82°F)

3. Flowering Stage: 20–26°C (68–79°F), preferably 2–3°C cooler at night

Over 30°C (86°F), photosynthesis may decline, trichome production may drop, and heat stress indicators such as leaf cupping, wilting, and chlorosis may appear. Managing temperature in warm areas within ideal ranges calls for proactive control and redundancy strategies.

Equally crucial is the awareness that temperature affects the metabolism, growth rate, water absorption, and the capacity of the plant to absorb nutrients. Unless complemented with sufficient watering and humidity levels, excessive temperatures could accelerate metabolic processes, leading plants to transpire more quickly and dry. Effective high-temperature cultivation is built on balancing environmental elements.

Insulation: The First Line of Defence Against Heat

Thermal insulation reduces heat entry; hence, it maintains consistent internal temperatures even with strong external variation.

Main Insulation Strategies:

- Use reflective insulation on ceilings and walls to reflect radiant heat.

- Use grow tents with insulated walls to build thermal barriers.

- Vapour Barrier Sealed Rooms: Air-tight grow rooms lower HVAC load and keep hot outside air from entering.

Especially on hot summer afternoons, appropriate insulation reduces the need for cooling systems and maximizes general environmental equilibrium.

Other methods that greatly lower temperature variation include insulated ducting and weather stripping on the door and ventilation input. Thermal imaging tools for spotting heat losses in the growing area allow growers to find weak spots in the insulation. Growers can achieve extraordinary temperature consistency even under climate circumstances marked by great temperature swings if they employ appropriate materials and sealing techniques.

High-Efficiency HVAC Systems for Hot Zone Cooling

Hot climates need a high-efficiency HVAC system investment. Usually, portable or low-capacity systems cannot handle continuous heat loads.

Recommended Procedures:

- Divide Air Conditioning Units: Provide improved energy efficiency and zonal temperature management.

- Ideal for large grow operations, inverter AC systems provide more stable room temperature with less cycling.

- Ductless mini-split systems provide strong direct cooling without the hassle of complicated ducting.

Verify that the device is properly sized for your area (in BTUs) and for light heat output and insulation efficiency.

Add smart thermostats with remote control and scheduling features to boost performance even more. Advanced systems can automatically adjust to changes in heat demand caused by lighting cycles, seasonal changes, or plant biomass expansion. Strategic vent and return duct placement guarantees consistent temperature distribution and the prevention of hot or cold areas, which could harm plant uniformity and health.

LED Lighting to Reduce Heat Production

Choosing a lighting system is crucial in tropical areas. Generally speaking, HID (high-intensity discharge) systems produce too much radiant heat, which causes temperatures to be overcontrolled.

Advantages of LED:

- Unlike HPS or MH lamps, LEDs produce relatively little heat.

- Well-built LED panels cover all phases of development with a spectrum.

- Modern LEDs make it easier to change intensity to fit plant needs and heat conditions.

Switching to LED lighting reduces the strain on HVAC systems and boosts energy efficiency.

LEDs will usually have passive or silent cooling technology as well, therefore eliminating the need for loud, heat-generating fans included in the fixture. Many commercial-grade LED systems will also have programmable spectra and scheduling capabilities, enabling growers to tailor wavelengths and exposure schedules to maximise growth without stressing thermal output. Energy conservation will help to justify the financial investment as the life cycle of an LED system increases, particularly in light of lower cooling needs.

Smart Airflow Management: Intake, Exhaust, and Circulation

The removal of heated air and the arrival of fresh, CO₂-enriched air require air exchange. Good airflow control guarantees consistent temperature distribution as well.

Parts of the Air Movement System:

- Draw cooler air from shaded or conditioned outside sources using intake fans.

- Remove hot air through charcoal filters or vent ducts using exhaust fans. Ideally, exhaust fans are located near the ceiling, where heat gathers.

- Deliver constant airflow across the canopy to avoid hotspots and moisture accumulation.

Thermostatically regulated fan systems provide automatic reactions to increasing temperatures.

Optimal airflow is also greatly influenced by duct placement. Putting intake vents close to the bottom of the grow room walls lets cooler air settle close to plant roots; ceiling-mounted exhaust blowers remove the heated air upward. Ideal for stealth and cleanliness, inline fan silencers and carbon filters eliminate noise and stink. In bigger businesses, zoned airflow systems and air curtains help stop microclimates from forming that would make them susceptible to viruses and pests.

Temperature Co-Control and Dehumidification

High grow room temps often coincide with high humidity levels, particularly in smaller spaces. Uncontrolled, excessive humidity causes powdery mildew, root rot, and mould outbreaks.

Suggestions for Environmental Control:

- Choose sizes suitable for the grow room space and install standalone dehumidifiers to prevent heated areas.

- To enable transpiration and nutrient absorption, aim to keep VPD in the most appropriate value range for the growth stage of the plant.

- Reduce VPD as evenings chill to help balance transpiration.

VPD charts and electronic hygrometers help synchronise humidity and temperature control systems.

A well-calibrated environment encourages the best stomatal performance, which directly affects the capacity of the plant to photosynthesise and absorb nutrients. Environmental controllers combined with temperature and humidity management can also regulate both variables simultaneously so that one does not accidentally cancel the other. In high-end growth, leaf surface temperature and humidity sensors at several canopy levels offer even more precise microclimate control.

Strategies for Emergency Heat Control

In hot areas, system failures or power outages can be disastrous. A backup mechanism guarantees survival under severe circumstances.

Methods of Heat Reduction:

- When the grid is down, backup generators offer necessary cooling and circulation systems.

- Block direct sunlight on windows or clear roofs using thermal curtains or shades.

- Evaporative Coolers (Swamp Coolers): Affordable, quick fixes in dry heat conditions.

- Low-tech emergency cooling system for small rooms or areas: ice buckles or frozen water bottles.

Preparation and redundancy: Keep your agricultural investment from unexpected temperature increases.

Including an uninterruptible power supply (UPS) in environmental control systems will give farmers precious minutes in a blackout. Battery-powered digital hygrometers and thermometers will continue to measure conditions in the dark, allowing farmers a view into the conditions even during system downtime. A heat stress checklist and an emergency ventilation strategy will help reduce losses during a critical temperature event.

Final Thoughts: Use Smart Climate Control to Beat the Heat

Warm climate temperature control depends on many methods, combining excellent insulation, efficient cooling, intelligent airflow, and careful monitoring. Growers can maximise their growroom temperature to offset high heating needs by adding the appropriate tools and a thorough approach. When correctly applied, these techniques will help safeguard your crop and enhance growth rates, flavour profiles, and total production potential.